Introduction to wheeled excavators:

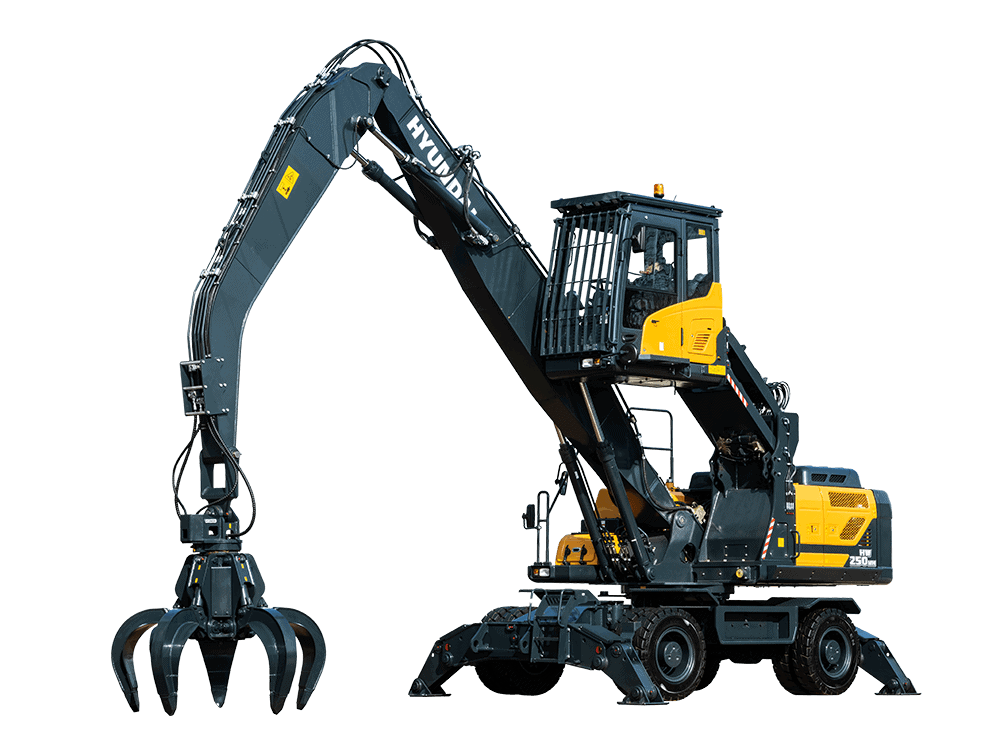

Wheeled excavators are a little bit different from traditionally tracked excavators. These are still relatively new to the market of the US but they have enjoyed popularity for a long time in Asian and European markets. Just like their different design their operation and maintenance are also different from the tracked excavators. This blog post is a guide on the operation and maintenance of wheel excavators.

Power and efficiency:

Wheeled excavators are just as powerful, productive, and efficient as tracked excavators. One drawback of a wheeled excavator is that some digging depth is lost because of the height difference due to the wheels. When the stabilizers are used, though, they often become better at lifting power than tracked machines. Because most of the wheeled machines have a retractable two-part boom so the lifting capacity can be increased further by shortening the boom.

Stability of wheeled excavators:

Some operations have expressed concern about the stability of wheeled excavators. When the outriggers are correctly used, a wheeled excavator is just as stable as its tracked counterpart is. A bit more care is needed on slopes because the center of gravity is a bit higher on a wheeled excavator. Otherwise, they are comparable when it comes to stability.

Work environment:

Wheeled excavators work very well for roadside work because they are maneuverable as compared to tracked excavators. Zero-tail swing models can work in a single lane without any problems. They don’t have as much traction off the road as tracked machines generally have. Uneven ground can also be a problem for them. Wheeled excavators mostly excelled in urban areas.

Applications of wheeled excavators:

Wheeled excavators can be used for a wide variety of applications such as scraped work, road work, material handling, waste handling, utility installation, and a few others. Some owners are using them as replacements for backhoes.

Cost:

Wheeled excavators tend to be more costly but they don’t involve the long-term expenses of maintaining an undercarriage and tracked system which accounts for a significant portion of the price for a tracked excavator. Dealers of wheeled excavators encourage potential buyers to consider not just the initial cost but the long-term M&O savings involved.

Benefits of wheeled excavators:

These can travel at a high enough speed that a lowboy isn’t needed for short distances. This makes a wheeled excavator quite a bit more convenient and reduces the need for a lowboy and CDL. Also, the wheels will not cause damage to the asphalt that tracks do.

How to operate a wheeled excavator?

Pre-shift check:

As you walk around your wheeled excavator before starting any operation first look for cracks, rust, or other damage. Inspect your attachment and ground-engaging tools (GET). Also, check under your excavator for any leaks and debris. Apart from this check these points as well.

- Fresh air cabin air filter

- Fluid sight gauges

- Diesel exhaust fluid (DEF) purges light

- Battery disconnect

- DEF, fuel, coolant, and hydraulic oil fills

- Engine oil check, filter, fill and sampling port

Safety tips:

Wear personal protective equipment (PPE) as required and keep your boots clean so you can safely maintain three points of contact when entering and exiting the machine. Here are some other important safety tips.

- Be mindful of pinch points and swinging/rotating parts

- In case of emergency, use the battery disconnect or engine stop control

Checking fluids and filters:

Fluids keep your wheeled excavator running optimally. If levels are low then you’ll eventually notice that the efficiency of the machine will go down and if you keep operating in this same condition its components can get damaged. Make sure you check.

- Levels Regularly

- Replace all fluids at recommended intervals as found in your operation and maintenance manual

- Take samples of fluids from analysis ports to determine when your excavator fluids need to be changed.

- Wheeled excavators are equipped with several different filters. These protect fluids and other equipment components. Keep checking and replacing filters as needed.

Lubrication and checking of hydraulics and other parts:

Grease helps parts on your wheeled excavator move smoothly which prevents premature wear. Keep fittings properly lubricated to help prevent costly downtime. Don’t forget to check the extra features on your equipment like:

- Light

- Tires

- Attachment and implements

- Hoses

- Bolts and fasteners

Basic operator settings:

Before operating your wheeled excavator moves the mirrors for a safe view of your surroundings. Adjust your seat for comfort and easy pedal/joystick reach, and also learn all the important buttons and switches located in your cab.

How to use wheeled excavator joystick steering:

If you want to cut down on fatigue and save a bit of time, joystick steering could be the solution. Instead of steering with the wheel and then moving your hands back to the joystick to control implements, you can keep your hands in one place. The feature works in gears 1-2 when you’re operating up to 9 mph (15km/h). If your cab is facing forward steering works as expected. That means when you move the thumb wheel to the left, your machine turns to the left. However, if your cab is facing backward, steering and travel speed pedal functions are reversed. Always refer to your operation and maintenance manual for guidance on maintenance, safety, settings, features, and more.

How to turn on the wheeled excavator joystick steering?

- Press the joystick steering button on the right control panel

- You’ll see the button’s indicator light turn on

- Use the left joystick thumb wheel to turn your excavator

- Press the button again to turn the joystick steering off

How to use wheeled excavator ride control:

One benefit of owning a wheeled excavator is it’s highly mobile. Unlike a tracked excavator, it can drive on finished roads and job sites while maintaining lift and digging capacity. But if you don’t use the ride control feature of your wheeled excavator you could have a very bumpy ride.

How to maintain a wheeled excavator:

Wheeled excavators are a tack of all trades type of machine in the world of heavy construction equipment. It can be used for digging trenches, loading heavy materials onto trucks, and demolishing a house, among many other uses. Most of the time, excavators are subjected to harsh conditions since they are operated in heavy rain, snow, or under the heat of the sun. Whether it’s a new or used excavator, if it is in good condition and fuel-efficient, it can lessen the operating cost. One of the most important parts of a wheeled excavator is the tires. Tires are a backbone of a wheeled excavator because they allow it to move. Just like the tracks of tracked excavator the tires or wheels of a wheeled excavator are made from rubber material so you must need to ensure that they’re not worn out.

There is also the electrical system which gets its power from a battery containing 12 volts of DC. You must check that the electrical system’s cable insulation is intact as faulty insulation can cause the electrical system to release a large amount of energy that can lead to overheating. Wheeled excavators also have filters that trap dust and debris, ensuring that the oil remains free from contaminants. To guarantee the efficiency of the excavator it’s very crucial to change the filters once in a while. Make sure to keep a record of your machine’s maintenance and repair information. Before operating the machine, run through the following checklist to avoid damage to the equipment and ensure your safety. Here are other key things which you need to do during the maintenance of your wheeled excavator.

- Check the level of fluids (Is there enough coolant? Are the engine oil and hydraulic oil levels correct? Are there leaks in the compartments and under the machine? Is there enough fuel?)

- Ensure that water is drained from the fuel/water separator

- Make sure the suspension of the tires is not too tight nor too loose

- Clean the radiator/intercooler

- Ensure that there is no irregular noise while the machine is running

- Check the dust ejector, bucket teeth, and wear plates

- Ensure that seatbelts, lights, alarms, and controls are working well

- Make sure coolers are free of debris

- Grease pins and bushings

Common maintenance issues in wheeled excavators:

To make sure your wheeled excavator works at full efficiency when needed, it’s recommended you educate yourself about the common maintenance and performance issues. Some may be caused by operator error, unintentional neglect, or just through constant use. Here are these common issues.

Hydraulic oil:

Hydraulic oil needs to be changed vigilantly as per the recommendations of the manufacturer. Mostly it’s between 2000-4000 hour timeframe. When checked, it may appear clean, but will eventually break down. By breaking down it means a loss of viscosity and ability to keep the contaminants suspended. If that’s the case then hydraulic oil will no longer protect moving parts in your wheeled excavator. It will no longer absorb moisture, and rust could build up. Always make sure to change the hydraulic oil before it appears cloudy.

Paperwork:

Although no one likes to fill out maintenance records it is important. Whether you still work with paper forms, enter data in a computer spreadsheet, or use a mobile phone application, it is still a tedious, time-consuming chore. Keeping track of records and bills of sale for oil changes, filter replacement, and other minor repairs is invaluable from a historical point of view. You can use that information to evaluate the long-term performance of your excavator and benchmark it against new equipment when you are in the market for your next wheeled excavator. Record keeping of maintenance cycles is vital when working with a dealer or the manufacturer for warranty repairs.

Lubrication:

The wheeled excavator has so many moving components which should be greased daily. Particularly if the machinery is used by multiple operators. Again, refer to manufacturer specifications about what kind of grease and quantity to use for each component like pins, bushings, and turntable bearings. One to three shots o grease are usually enough so never use more than what is recommended.

Propel drive gearbox:

Exposed to the elements, this component will pick up its share of dirt and debris and needs to be treated with utmost care. Clean the fill and drain plugs regularly and remember to change the oil every 1,000 hours or whatever the manufacturer has recommended. Although propel drive gearbox is a small thing in an excavator but it is expensive to replace. As time passes you will become more familiar with how your excavator operates and may even identify other maintenance issues which need regular attention. Each piece of machinery is different and needs to be cared for as such.

Managing the operating cost of your wheel excavators:

The cost of ownership. As we mentioned, the price for a new mini excavator can vary, but you must predict the cost of the machine to understand its true value. Besides the purchase price, you also will pay for: Tires (these normally are separate from the selling price of the excavator), taxes on the purchase price, interest paid if you finance the purchase, annual insurance, and residual value.

Consider the operating expenses of the machinery. Beyond the cost of ownership, you also must factor in perhaps the most expensive component of operating the excavator, and that is the operator himself (or herself!). As an example, your employee makes $33 an hour and spends 750 hours each year digging or moving earth; that equals $24,750 a year in wages and benefits. Next, estimate the cost of fuel at $4 a gallon, and your machinery burns through about 3.2 gallons per hour, or $12.80 an hour in fuel; when you multiply that by 750 hours, you are looking at $9,600 a year in fuel costs. Finally, if you factor in a certified project manager working a few hours each week on different job sites, plus the cost of tires, repairs, and other maintenance items, your total operating expenses for the year could be more than $40,000. Keep in mind that these numbers will vary based on your circumstances.

Conclusion:

If you are doing most of the work in a more urban setting, then you might want to consider a wheeled excavator. Although initially a bit pricier but they said to save money in the long run because there are no added expenses of maintaining a complex undercarriage. These machines are stable, powerful, and versatile enough to perform a wide variety of tasks. For more information, please contact us.