A few decades ago, Mini excavators were introduced but now they have a big name and fame in the construction industry. Mini excavators are widely used in construction projects with their notable performance in narrow and small areas.

Mini Excavators have ease of operation, a small footprint, low cost, and precise operation for landscaping, digging, and trenching. The mini excavator is vulnerable equipment that requires regular maintenance. Daily maintenance helps to avoid several issues that are time-consuming and costly. We have included general information about how to operate a mini excavator efficiently and safely.

The most important factor is how to operate the excavators in the best way. Operators should implement regular maintenance for the adjustments of the assets. These machines have higher usage demand for best utilization.

How to Operate Mini Excavators

The operators learned all the necessary information for the best operating system of the excavators. It enhances the maximum age of the equipment. Before starting the mini excavators, Operators should check all affiliated parts and attachments. The operator collected the necessary information about the machine downtime, average time, and how to replace the parts. These cautions enhanced the cost and conditions of the assets.

Baseline operating information

The operator should adopt a maintenance strategy or achieve the best results. Companies introduced a manual or computerized system, which is used for maintenance. A few decades

- Selection of a Mini Excavator: Mini Excavators came in multiple sizes, ranging from super less than 4000 pounds, to heavyweights. For simple small digging need the smallest size of Mini Excavator. 3 or 3.5-ton Bobcat 336 is a better choice for landscaping projects.

- Study the operator’s manual: After studying this manual, the operator is going to make sure about the exact location of the controls. Quality mini excavators’ brands like Kobelco, Bobcat, Case, and Kubota are providing a detailed manual that described how to operate mini excavators.

- Pay Attention to the warning labels and damaged parts: Operators should pay attention to the specific warning labels during operating. The operator must look for oil leaks, fluids dripping, lose control cables, and linkages. Users will also notice the maintenance information, so the machines can perform their duties more efficiently.

- Maintain a clear area to try the machine: Mini Excavators have a stable and good balance with fairly wide footprints. Sometimes, they are overturned, so always check and start on firm ground.

- Sit in the operator’s seat and Mount the machine: Operators should look around at the controls, gauges, and restraint system. The use of a seatbelt is necessary to keep safe inside the machine’s cage. The operator will set the arms control on the left side of the machine flips up to access the seat. Pull the lever on the front end, and then the whole thing will swing up and back.

- Use the joysticks and steel rods with handles for the movements: Sticks are used for controlling the bucket assembly. So the machines are maintained the rotating function of machines during operations. Steel rods control the rotation and push them to move forward. Operators should be made sure about the direction of the tracks.

- Start your machine. During the engine running, the operator should be careful for avoiding accidents. Because any movement of these controls will cause the instant change in your machine the sticks are located very close together and the Operator can control one stick with each hand. The user moves the machine around a bit, then turns and backs to get handling and speed of it.

- Find a suitable place for practice

- The armrests control the boom, pivot, and bucket motion, and are operated in two modes, called backhoe or track hoe mode. The operator should keep practicing with these controls until he or she has a good feel for what they do.

How to Maintain Small Excavator

Compact and Mini excavators are popular in the equipment industry. Mini Excavators have less cost and fewer maintenance expenses. Excavators have flexible accommodation abilities to maintain a variety of attachments. Mostly, Compact excavators are used in urban areas for different services. Agricultures and farmers are also purchasing these machines for different services. Compact excavators are versatile and durable. These machines required require regular maintenance to stay in good condition. The manufacturer’s maintenance guide has all details about the maintenance of the Excavators.

- Regular Check the Engine and Hydraulic oil levels

Engine and Hydraulic oil levels should be checked daily and maintained according to the need. All machines are manufactured with slight differences, so should be consulted the excavator manual. It will provide guidelines, how to change the oil and keep the maintenance. The main reason for Hydraulic failures is the contaminated oil.

- Use the Quality oil

Low-quality oil creates many problems for the excavators. Quality oils are formulated to avoid both thermal and oxidative breakdowns. High-quality oils are also improving soot-related viscosity control and wear protection. Hydraulic systems have endurance ability, but the low oil will lead to hydraulic failures. Low and cheap oils have additives that break down the machine power during high-duty cycles. The use of hydraulic oil keeps the quality condition of the excavators. Good hydraulic oil and viscosity are fundamental for anti-corrosion and anti-wear additives during high heat conditions. A regular oil sample is recommendable.

- Regular Check Water and Fuel separator

Advance excavators have a fuel filter with a water separator. Fuel filters remove water from the fuel. Daily inspection and regular draining should be maintained for this type of fuel filter. If the oil has the best quality and standard, so have the fuel also. During long work, often fuel to be contracted. It is the responsibility for delivering the correct fuel and ensuring the cleanliness of the fuel. It will also make sure that the fuel contains the proper additives. It prevents the fuel from the growth of algae and other organisms. It is important to check the fuel tank vent because here becomes clogged during working in dusty conditions. It is also leading to over-exertion on the fuel pump during delivery.

- Regular Check the cooling system

Radiator insulation and heat shields should be in the correct places. If any wear developed in these compartments then should be replaced. Heat exchangers parts of the excavators should be properly checked and maintained. Coolant or oil leaks also cause the build-up of dust and debris. It slows the passage of air; as a result, the insulator is lessening the heat exchange. The coolant is replaced according to the manufacturer’s recommendations. Because coolant’s additives are stopped the working conditions and is lead to engine failure.

- Regular check the lubricated pivot points and attachments

All attachments have frequently lubrication, so must be used high-quality grease. These attachments are the boom, dipper, bucket, all pins, and busting. Sufficient and proper lubrication is the key to long-lasting equipment. False greasing is also a cause of environmental hazards. Quality grease and oil fire are all types of hazards the attachments should be checked daily during operations to avoid cracks and wear. These attachments are used for heavy-duty, then required a quick change.

- Maintain Track adjustment

Track adjustment should be maintained daily for the heavy duties. Too tight track leads to premature wear and breakage. In contrast, a too loose track becomes a cause of poor maneuvering and de-tracking. A properly adjusted track will increase longevity and decrease the wear on the track.

- Regular Services of the gearbox and leaks

Gearbox requires a regular oil change and maintenance service. It maximizes the productivity of the excavators. All leak points should be checked and maintained daily. Always monitor the fluid levels for preventing oil leaks. The operator must inspect the cooling system, the hydraulic system, and the swing drive.

Put Together Maintenance Checklists

Maintenance equipment should be well checked and ready on regular basis. For accurate implementation, service events are listed down. We should also develop a preventive maintenance checklist to monitor repairs and adjustments.

- Lighting

- Electrical

- Safety

- HVAC (heating, ventilation, and air conditioning)

- Buildings

- Fixtures and furniture

- Plumbing

Conclusion

We recommend, operating and maintaining a long life with minimal downtime and maximum efficiency, we should follow the guidelines for maintenance. Always should be checked and changed the gear oil, greasing the pins, and operating excavator correctly. Changing oil should be maintained according to the hydraulic fluid per manufacturer recommendations.

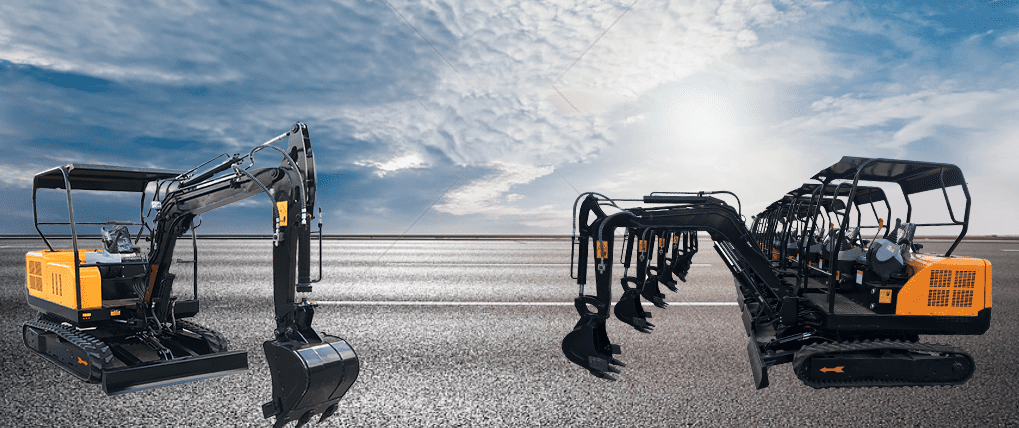

Contact Hiosen Company for All Your Mini Excavator Needs

Hiosen Company has been here to help for achieving success in construction projects. We offer multi-ranged mini excavators with different sizes and capabilities. Contact us and get more information.