With the development of modern society, excavators especially mini excavators have been playing an important role in construction sites. As we all know, excavators consist of a boom, stick, bucket, and cab on a rotating platform known as the upper structure. This upper structure sits on the top of an undercarriage with tracks or wheels. Excavators are stable, reliable pieces of equipment, but conditions at work sites are not always ideal, and under certain circumstances, they can slip, topple, and fall.

If you are a contractor or a construction company owner or an excavator operator, Safety is an important consideration in any type of construction or excavation site.

You might agree that adherence to the safety and maintenance tips not only keeps the equipment in the good condition but give you peace of mind too that the equipment will not show signs of depreciation too early and can be used efficiently for years together with high uptime. Also, there are a few basic strategies that workers, site supervisors, and others can employ that help to keep the number of excavator accidents as low as possible.

The Common Problems of Operating An Excavator

There are a couple of common hazards that anyone using an excavator should be on the constant lookout for:

1. Overloading the excavator

This can happen most commonly when using the machine in crane mode and can lead to a weakening of the excavator structure, in turn becoming a health and safety risk.

2. Not understanding how to properly use the excavator

Misuse from inexperienced operators is one of the most common safety risks with regard to excavators. This is not just a risk to the operator; it is not uncommon for pedestrians or other vehicles to be hit following poor control of the excavator on public roads.

3. Power lines

Underground power lines are an obvious concern for those using excavation equipment. To avoid problems, call the power company to get a detailed understanding of where those are before commencing a job, but if a job is within 10 meters of overhead wires, these need to be carefully monitored, too.

These risks need to be taken seriously. Over a period of three years in NSW alone, over 140,000 people have been injured by improper use of machinery. Of those, 5,800 were permanently disabled and 121 died.

Knowing the problems of operating the excavators, we have to know how to prevent these in some ways.

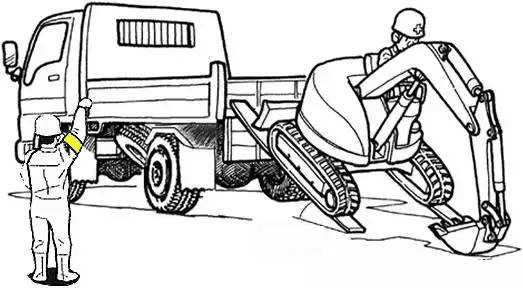

5 Ways to Keep Mini Excavator Safety During Transporting

1) To use a sloping plate suitable for transporting vehicles or construction machinery, set the angle of the sloping plate to less than 15 degrees.

2) In addition to prohibiting others from entering the work area, a work commander is also required on site.

3) Discuss the work order and method in advance, and then clearly inform the relevant personnel.

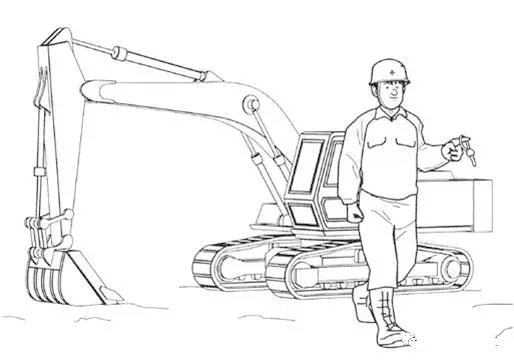

4) When leaving the driver’s seat of construction machinery such as a hydraulic excavator, lower the bucket, stop the engine, and remove the key. Also, lock the safety locks such as the operating lever.

5) For the clothing of the operator, make sure that the buttons and straps of the sleeves, hem, etc., are not hooked to the operating rod.

10 Safety Tips Before Excavator Operation

Before starting your excavator, consider the following safety tips to ensure you are fully prepared for operation:

- Read the operators’ manual to get familiar with the controls of the equipment

- Visually inspect controls, engine compartment, undercarriage parts, hydraulic parts, and other parts and see that everything is in proper condition

- Walk around the equipment and check loose bolts, trash build-up, oil leaks, or damaged parts.

- Check that there is no damage to the crawler during the inspection before starting the operation and the regular self-inspection. If any problem is found, it should be repaired and repaired in time.

- Fasten the seat belts for comfort and security.

- Make a quick check of the controls. Be sure the control levers are operating properly. Also, make sure the track is in good condition.

- Check the propel system. It’s better to do this before operating so you can prevent accidents on the job.0

- Call the area’s utility services to have the job site marked for underground lines or structures.

- Switch on the key and check for any diagnostic codes or warning alerts that are active. Rectify the code before starting the operation

- Test the machine before going to work to see whether it is in good condition.

14 Tips During Operation of Excavators

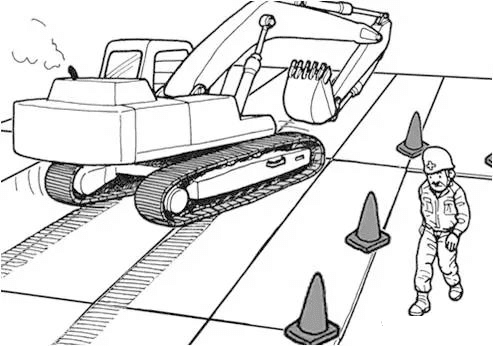

The most effective way to reduce excavator accidents at a job site is to make sure that everyone should understand how the excavators work. This includes having some idea of how the equipment moves, the amount of space required for the equipment to make use of a full range of that movement, and why it is important to remain a minimum distance from the excavator while it is in operation.

1) When the hydraulic excavator is working, no one is allowed to enter within the turning radius. Also, no one should be allowed to enter the cab or anywhere else of the machine.

2) To be equipped with a commander to give work instructions.

3) Only operate the excavator while you are sitting in the seat and in full control

4) Do not perform the sudden turning operation of the hydraulic excavator on a narrow site.

5) Try to control the speed while walking on rough terrain or within congested areas

6) Choose the road as flat as possible during excavator walking. Steer the machine slightly and only make small gradual changes in direction when turning is needed.

7) The boom and arm should be extended with the bucket lowered and rolled out when driving up the slopes. This can help in dropping the bucket and preventing the equipment from sliding.

8) The bucket bottom should be kept low and parallel to the ground when moving down the slope

9) When using the excavator for trenching, make sure the machine is horizontal by placing dirt underneath the tracks. That could make the trench vertical and will help to avoid cave-ins

10) During an operation on slope areas, try to level the machine by digging a shelf. Materials removed from the upper slope can be used to build up the lower slope and create a level surface.

11) On steep bench cuts, you need to cut appropriately away from the upper bank to allow for adequate swing clearance when casting down the slope

12) Make sure you will never dig or trench directly underneath the excavator

13) When you are lifting obstacles, you should check the hook before starting the operation.

The anti-dropping device of the hook is always available and does not stay under the suspended objects.

14) When loading material such as soil or sand, never swing the bucket above the cabin. Because the material could fall down anytime.

Safety Tips After The Operation

- Choose the right place to park. Such as a level surface with the bucket attachment lowered to the ground.

- Hydraulic system pressure is to be released by moving all the hydraulic controls several times until release the system pressure is completely from the circuit. The key switch & hydraulic isolation switch are to be in condition during this process.

- The hydraulic lock should be turned off.

- Ensure that the engine runs at half throttle without load for a few minutes (2-4min) to help cool the turbocharger down.

- Shutting the engine off, the RPM should be set to low idle.

- Before leaving the excavator, remember to lock the cabin.

Conclusion

Excavators are one of the most machinery equipment used in construction areas. We have to keep the safety tips above in mind. And choose a reliable excavator manufacturer is the first step. Most excavator suppliers could provide the basic manual for operation and safety. We should follow that and operate the excavators carefully.

If you have more questions about excavators’ operation safety, or anything else, kindly please contact us.