Introduction

Mini excavators are becoming popular across different industries due to their performance and efficiency. Different famous brands such as Kubota, John Deere, Bobcat, Komatsu, Hitachi, and Caterpillar are leading manufacturers of mini excavators. No matter which brand you prefer, you have to maintain your mini excavators regularly.

Without missing a beat, mini excavators can perform all kinds of tasks due to their versatility. These are not just good for construction site digging but capable of performing various other tasks. For example,

- Farmers use it for materials handling and fences installation tasks.

- Landscapers utilize mini excavators for planting trees, installing hardscapes, and trenching.

Due to such applications, these machines are manufactured on a large scale in China. However, Just like any other equipment in this mortal world, mini excavators also need regular maintenance.

Different famous brands give their maintenance plans with their mini excavator. If you haven’t gotten a maintenance plan and need some guidance, this blog is the right place for you. Continue reading!

Guidance To Run Your Compact Excavators At Peak Efficiency

When working with your mini excavators, you have to keep working on two main things together. The first one is to keep your mini digger in high-quality working condition. While the other one is to follow your manufacturer’s instructions about the safety of your mini excavator. Ignoring the second option can have a quite negative impact on the first one. This indicates that you must operate your mini digger safely while following maintenance guides.

From getting small jobs done to trenching in large field areas, a mini excavator can be your perfect partner.

Safety Protocols Before Operating Your Mini Excavator Machine

✓Make sure the manufacturer has permitted you to use a mini excavator at your site.

✓Make sure there are no excessive cracks, damage, or wear on the bucket. If rust is found, try to replace the parts as soon as possible.

✓Make sure there are no leakage points in the bucket cylinder.

✓You should replace the stick if it gets cracks due to daily beating.

✓Inspect the boom cylinders since they also get damage and cracks.

✓Make sure there are no signs of leakage, pieces of debris, or cracks underneath the mini excavator. Such a situation can impose risky situations on tracks or tires.

✓Don’t forget to inspect the car body in terms of cracks and damage.

✓Inspect the air filter to make sure there is no dirt and restrictions.

✓Inspect windshield wipers to make sure there are no splits. It is important to maintain a standard fluid level for your windshield wiper.

✓The coolant level of the engine should also be maintained.

✓Try to avoid mini excavators usage in extreme weather conditions.

✓Inspect the controls and gauges to ensure their proper working.

✓Inspect the lighting bulbs to ensure they are working well.

✓Make sure there is proper adjustment of mirrors.

✓Make sure the oil level is balanced in the engine compartment. The compartment should be free of debris.

✓The fuel water separator should be drained.

✓Make sure there are no missing nuts, guards, bolts, and bumpers.

Most Recommended Instructions By Experts

✓First of all, you should sit inside your excavator’s cab. Before running it on the job site, you have to check it in terms of damages on mounting, gauges, indicators, lights, alarm, and overall interior.

✓The mini excavator cannot be operated by more than one person.

✓You should never transport the working staff in the bucket.

✓Inspect the ground carefully and make sure there are no damaging materials that may affect the quality of your excavator. You have to keep in mind that your mini excavator can be durable but not indestructible.

✓Inspect breaks as well as steering wheels. It can make you stop and resume the task when required.

✓Don’t exceed the capacity of your mini excavator.

✓When using a mini excavator at your job site, you shouldn’t forget to wear safety equipment. It is because the mini excavator operator may be hit by materials flying away.

✓Drive your mini digger at a distance from your co-workers or animals at the site.

✓Make use of a boom in an upward and downward movement when you are running on slippery ground.

✓When performing an inspection, you should not leave the machine running.

✓You should remove attachments while your machine is already operating.

✓When you are done working with your compact excavator, you should turn it off, lock cab doors, and place the keys somewhere safe.

Proactive Maintenance To Increase Business Productivity

It is to be remembered when using heavy construction machinery, the downtime will lead to lost revenue. From the end of one job to the beginning of the second job, downtime is one thing to consider. But the inability to use your mini excavator due to some maintenance issues is another thing to consider. Therefore, you cannot underestimate the importance of maintaining your mini excavator once your job is done.

You will be surprised to know that a lot of professionals don’t pay attention to the proactive maintenance of their mini diggers. At this point, you can face downtime due to negligence in maintaining your mini digger properly. You can follow the maintenance strategy in three possible ways.

- You should be able to understand your mini excavator’s power capacity and the requirements of your business.

- You should adhere to maintenance plans given by your manufacturer.

- You should know the maintenance needs of your mini digger and take care of it accordingly.

No one can know your business better than you and it can ensure profits and growth to understand it better. You can decide carefully what kind of equipment can help you meet your objectives. For example, you can select and maintain your mini excavator models for your business according to the following questions :

Questions To Consider :

?What kind of tasks your company will perform with a mini excavator?

?Do you have to go for small-scale home-level projects or large-scale building construction-related projects?

?What type of ground surface conditions you will be navigating?

The answer to all these will help you define the purchase of the right mini-excavator and maintain it in the right possible way.

Different major brands have their own maintenance plans. You can follow them to increase the productivity of your business on regular basis.

Regular Maintenance Tips For Mini Excavator Equipment

✓Check battery levels for electrolyte levels and connection problems.

✓Check hydraulic losses and tube lines to make sure there are no signs of wear and tear.

✓Check the engine compartment and the belts in it.

✓Check joysticks, steering levers, wheel nuts, foot pedals, hand controls, and parking brakes.

✓Maintain oil levels of compact excavators for final drive transmission.

✓Maintain grease on pinion and swing circle.

Recommended Time For Servicing Of Your Mini Digger

✓After every 10 hours, you should inspect and add fluids to your engine, radiator, and hydraulic.

✓After every 50 hours, you should adjust and inspect the tracks to ensure proper tension levels

✓After every 250 hours, you should inspect the battery to check if it needs to be cleaned.

✓After every 500 hours, there is a need to change the oil in the engine as well as the filter.

✓After every 5000 hours, experts recommend changing the hydraulic oil even if it doesn’t appear cloudy or dirty.

✓After every 2000 hours, you should inspect the radiant coolant and change it if necessary.

✓Lastly, the swing reduction gear case should be changed after every 1000 hours.

Maintaining The Undercarriage Of Mini Excavator

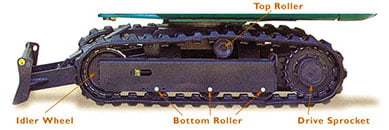

The undercarriage of your mini digger plays an important role in running it from one point to another point. You have to take a look beneath your compact excavator and notice the moving parts. All these parts are necessary to maintain your compact excavator. Here are the most important things to do in order to maintain your compact excavator :

Golden Tips To Maintain Undercarriage:

- Cleaning is the most important thing to do while maintaining the underneath. Not only undercarriage but it also applies to the interior as well. You should remove tree roots, rocks, dirt, and debris.

- If there are any missing components in the Undercarriage then make sure to remove them. Otherwise, it may affect the performance of the mini excavator.

- You should opt for wider turns while moving your excavator. Spend less time working on slopes. You have to make less aggressive and wider turns by reducing track spinning. You should not drive your compact excavator on harsh tracks that are full of concrete and debris.

- Ensure proper tension maintenance on your steel or rubber tracks. Keep in mind that you have to adjust it according to the conditions of the ground.

- Since excavators are being used mostly for sensitive and soft surfaces, therefore, rubber tracks are considered ideal. It has greater floatation as compared to steel tracks.

- The undercarriage has more interaction with the job site. Therefore, you need to be careful while operating a mini-excavator especially when you are digging through it.

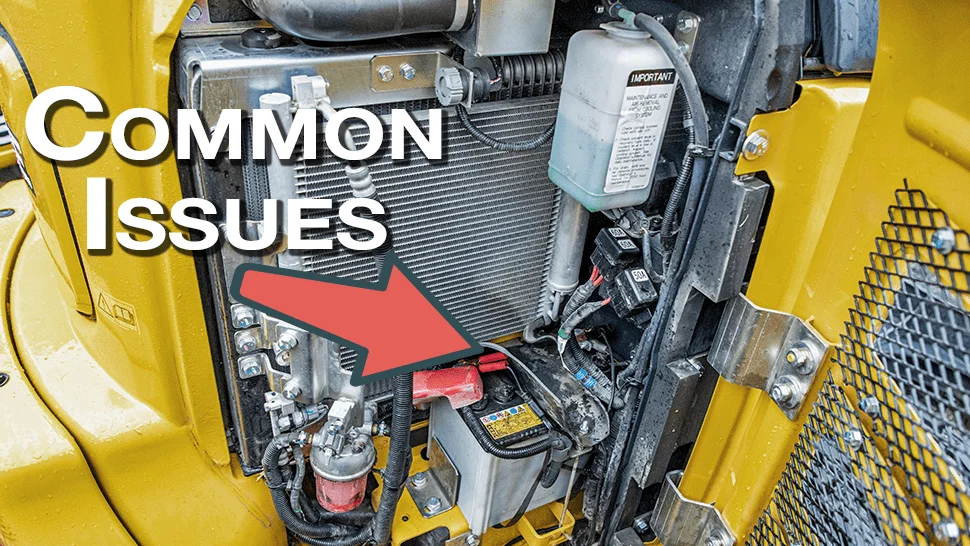

Common Maintenance Issues With Mini Excavator Machines

🗴You have to change hydraulic oil regularly based on your manufacturer’s instructions. If it gets cloudy, it will not be able to protect moving parts from rust.

🗴You have to keep a record of maintenance in your computer or paper form. It can be time consuming and tedious process.

🗴You have to grease the parts on daily basis according to manufacturer instructions.

🗴Adjust track tension according to ground nature. In most cases, companies have to go through big losses due to the selection of the wrong track in terms of rubber or steel.

🗴Maintain propel drive box according to manufacturer’s instructions. It is small and easy to forget but it may cost you a lot if not maintained.

Management Of Compact Excavator Operating Expenses

When you are a small business owner, you need to manage Excavator expenses more carefully. At this point, it is important to realize that you should purchase it from a good dealer. In this case, you may have to spend a little more but you will definitely get a quality product. Maintaining your mini excavator is one part but taking care of its expenses is another new problem. Follow the tips listed below to maintain management expenses :

Expenses Management :

1. You have to keep in mind that apart from excavator price, you also need to pay for taxes, tires, residual value, fuel, oils, and annual insurance. Therefore, you have to arrange the price accordingly.

2. According to research, the average maintenance cost repairing of your excavator can be more than $40,000 per year. So you have to arrange this amount for performance efficiency. However, this cost may also vary based on features such as the working hours of mini excavators, model, operating weight & dig depth.

When you are a business owner, you have to keep in mind the factors that might affect profitability. An expert mini excavator operator may cost you higher than a beginner operator. A used compact excavator may not have more cost but you may end up spending more on its maintenance.

Final Thoughts

If you want to have years of care-free work then maintenance is the most important thing to consider. The more you Maintain it, the better it will perform. Maintaining it can also increase its average lifespan. However, don’t forget to consult your manufacturer for its maintenance. If you want the right mini excavator with the right maintenance guide and planning, you can search on Google & Contact Us now.