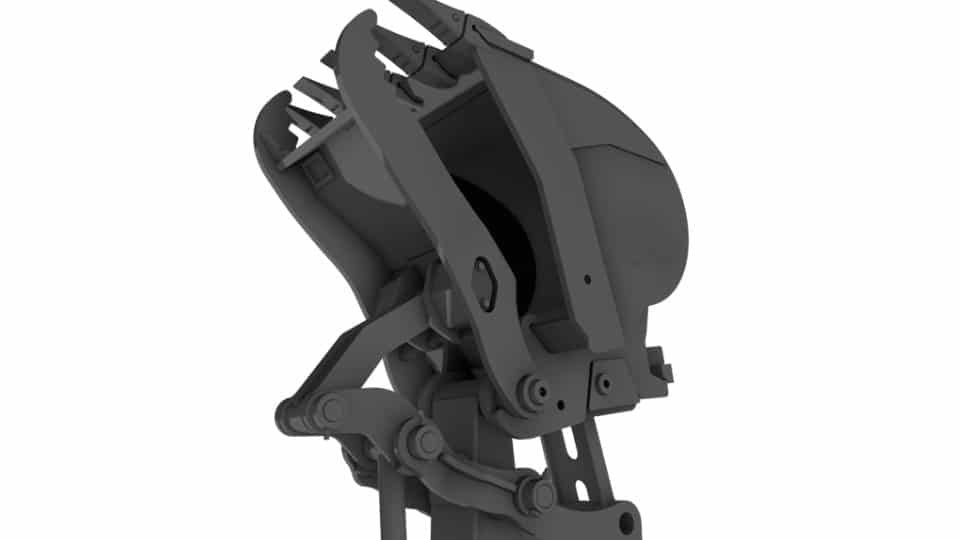

A mini excavator thumb is an attachment for a mini excavator used to grip and hold onto objects such as rocks, logs, and debris. It is designed to provide additional functionality to the mini excavator, allowing it to handle a wider range of tasks.

The thumb is steel and attached to the mini excavator’s arm using bolts and a mounting plate. It uses the excavator’s hydraulic system to easily open and close to grip objects.

Some benefits of using a mini excavator thumb are increasing versatility and productivity and improved safety. With a thumb attachment, the excavator operator can more easily manipulate and move objects, reducing the need for manual labor and increasing efficiency on the job site. Furthermore, the thumb can help to prevent objects from slipping or falling, reducing the risk of accidents or injuries.

Types of mini excavator Thumb

Several mini excavator thumbs are available, each with a unique design and functionality.

Fixed Thumb:

A fixed thumb is a basic thumb attachment that is bolted onto the end of the excavator’s arm. It is designed to provide a solid gripping surface for objects, allowing the operator to pick up and move them easily. Fixed thumbs are relatively simple in design and are often the most affordable option.

Mechanical Thumb:

A mechanical thumb is a more advanced type of thumb attachment that the operator can operate manually. It is attached to the excavator’s arm using a pivot joint, allowing it to be moved up and down to grip objects. Mechanical thumbs can provide greater control and precision than fixed thumbs, making them ideal for more complex excavation tasks.

Hydraulic Thumb:

A hydraulic thumb is a type of thumb attachment that is operated using the excavator’s hydraulic system. The operator can open and close the thumb using controls in the excavator’s cab. Hydraulic thumbs can be more expensive than others, but they offer greater versatility and ease of use.

Progressive Link Thumb:

A progressive link thumb is a type of hydraulic thumb that is designed to provide maximum gripping power. It uses links and joints to create a more flexible gripping surface, allowing the operator to pick up irregularly shaped objects more easily.

Clamshell Thumb:

A clamshell thumb is an attachment designed to scoop and lift materials rather than grip them. It consists of two large blades that open and close like a clamshell, allowing the operator to scoop up material and move it to another location. Clamshell thumbs are often used for landscaping and material handling tasks.

Sizing chart of mini excavator Thumb

Here is a sizing chart for mini excavator thumbs based on the weight class of the excavator:

| Excavator Weight Class (in metric tons) | Thumb Width (in inches) | Thumb Length (in inches) |

|---|---|---|

| 1.0 – 2.0 | 8 – 10 | 24 – 30 |

| 2.1 – 3.5 | 10 – 12 | 30 – 36 |

| 3.6 – 5.5 | 12 – 16 | 36 – 42 |

| 5.6 – 8.0 | 16 – 18 | 42 – 48 |

| 8.1 – 10.0 | 18 – 20 | 48 – 54 |

How to work safely with mini excavator Thumb

Working safely with a mini excavator thumb requires proper training, equipment, and adherence to safety protocols.

Ensure Proper Mounting:

Ensure the mini excavator thumb is properly mounted and secured to the excavator’s arm before use. Check the bolts and mounting plate to ensure they are tightened to the manufacturer’s specifications.

Inspect the Thumb:

- Before using the mini excavator thumb, inspect it for any damage or wear.

- Check for cracks, bends, or other signs of damage that could affect its performance or safety.

- If any issues are found, do not use the thumb until it has been repaired or replaced.

Use Proper PPE:

You should wear appropriate personal protective equipment (PPE), such as a hard hat, safety glasses, gloves, and steel-toed boots. It will help protect you from any potential hazards on the job site.

Follow the Manufacturer’s Guidelines:

Follow the manufacturer’s guidelines and recommendations for using the mini excavator thumb. It has recommended weight limits, operating procedures, and maintenance requirements.

Be Aware of Surroundings:

Always be careful of your surroundings when using the mini excavator thumb. Watch for other workers, bystanders, and potential hazards such as underground utilities, overhead power lines, or unstable ground.

Use Caution When Gripping Objects:

When gripping objects with the thumb, use caution and ensure that the object is properly secured before lifting or moving it. Do the weight limit of the thumb, and be aware of the excavator’s capacity when lifting heavy objects.

Properly Store the Thumb:

When the mini excavator thumb is not used, properly store it on the excavator or in a designated storage area. It will help prevent damage and ensure it is ready for use.

How to remove the mini excavator Thumb

Removing a mini excavator thumb requires some basic knowledge and tools.

- Position the excavator on level ground and lower the bucket to stabilize the machine.

- Turn off the excavator and disconnect the hydraulic hoses that connect the thumb to the hydraulic system. Make sure to plug the hoses to prevent any hydraulic fluid from leaking.

- Remove the pins and bolts that attach the thumb to the excavator’s arm. Depending on the type of thumb and attachment method, you may need to use a hammer or pry bar to loosen the pins and bolts.

- Use the excavator’s boom and bucket to lift and remove the thumb from the excavator’s arm. Carefully lift the thumb and place it on a flat surface or in a designated storage area.

- Once the thumb is removed, store it safely and securely. Replace the pins and bolts in their original locations on the excavator’s arm, tightening them to the manufacturer’s recommended torque specifications.

- Reconnect the hydraulic hoses to their locations on the excavator and ensure they are properly secured.

How to choose a mini excavator Thumb

Choosing the right mini excavator thumb can improve your efficiency and productivity on the job site.

Compatibility:

The thumb is compatible with your mini excavator. Read the manufacturer’s specifications to ensure that the thumb you select is designed to work with your particular model and size of mini excavator.

Size:

The size of the thumb is another important consideration. Choose an appropriately sized thumb for your mini excavator and the tasks you will be performing. A thumb that is too small may not be able to grip large or heavy objects effectively, while a thumb that is too large can find it difficult to maneuver in tight spaces.

Weight Capacity:

The thumb’s weight capacity is another important consideration. Ensure your thumb is rated to handle the weight of the objects you lift and move.

Thumb Type:

There are several types of mini excavator thumbs to choose from, including fixed thumbs, hydraulic thumbs, and mechanical thumbs. Consider which thumb type will work best for your specific needs and budget.

Material:

Thumbs are typically made from steel, and the quality of the steel can affect the thumb’s durability and longevity. Look for a thumb made from high-quality, heavy-duty steel that can withstand the rigors of daily use.

Brand and Price:

Consider the brand reputation and price of the thumb. Look for a thumb from a good brand with a good track record and reliable, high-quality attachments. However, consider your budget and select a thumb that provides the features and capabilities you need at a price you can afford.

Conclusion

The mini excavator thumb is a useful attachment that can increase your efficiency and productivity on the job site by allowing you to precisely grasp and manipulate objects. Following proper safety procedures and maintenance guidelines can help ensure that your mini excavator thumb performs optimally and lasts for a long time. If you need any detail, you can contact us.

.