Today, mini excavators are an important part of the construction industry. They are used in a variety of applications from digging trenches, and building foundations, to demolishing old buildings.

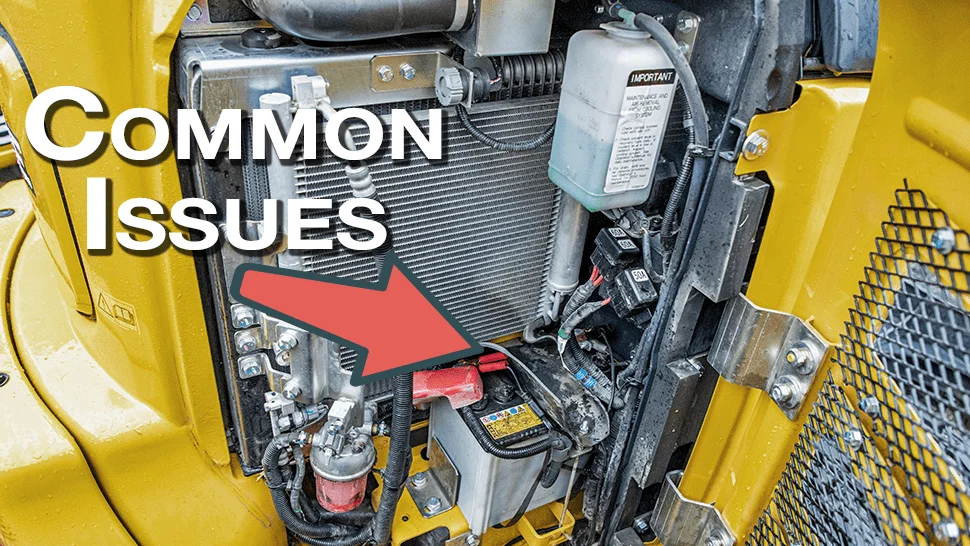

However, excavators are not without their problems.

Although mini excavators are one of the most useful pieces of equipment that people use to serve various purposes, they can also be one of the most frustrating. There are a plethora of problems that people face with this equipment even if they buy this tool to ease their life.

Fortunately, most of these problems have fairly simple solutions that don’t require a lot of time or money to fix.

Here are some of the most common mini excavator problems and ways to solve them:

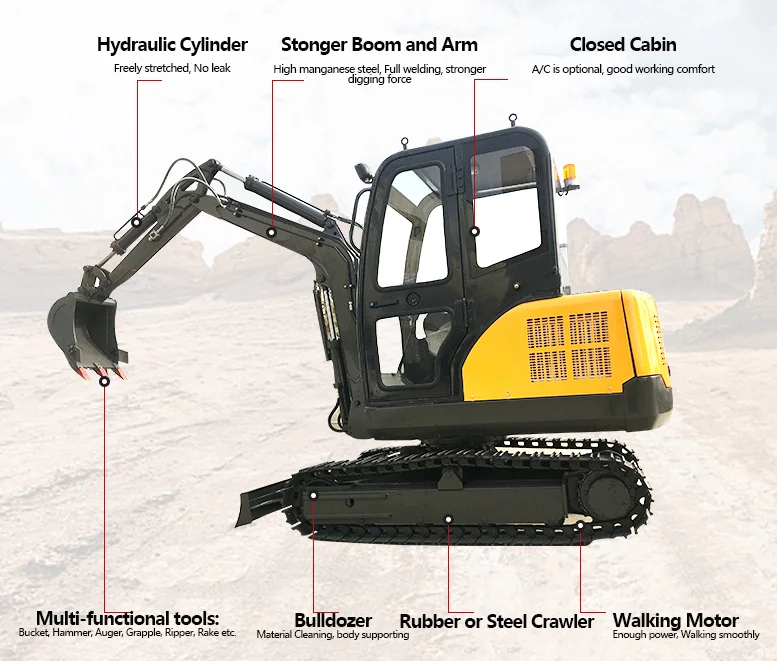

1. Hydraulic Leaks

The Hydraulic leak is one of the most common excavator problems. A hydraulic leak can occur for a variety of reasons, but the most common cause is wear and tear on the seals and gaskets.

To fix a hydraulic fluid leak, you will need to replace the seals and gaskets.

Here’s how to replace hydraulic seals in a mini excavator:

- First, you’ll need to remove the old seals. To do this, you’ll need to use a seal removal tool. You can purchase the equipment required at any local hardware store.

- Next, you’ll need to clean the area around the seals. This is important because you don’t want to contaminate the new seals.

- Now, you’ll need to install the new seals. To do this, you’ll need to use a seal installation tool.

- Finally, you’ll need to test the seals. To do this, you’ll need to pressurize the system and check for leaks. If you find any leaks, you’ll need to adjust the seals until the leaks stop.

- Once you’ve replaced the hydraulic seals, your mini excavator’s hydraulic oil stops leaking.

2. Engine Trouble

This is another common problem with excavators. The most common cause of engine trouble is dirty fuel.

To fix this problem, you will need to clean the fuel system.

- Open the access panel to the fuel system. This is usually located on the side of the engine near the bottom.

- Disconnect the fuel line from the fuel filter. Place a drain pan under the filter to catch any fuel that may spill out.

- Remove the fuel filter from its housing and discard it.

- Install a new fuel filter into the housing, making sure it is properly seated.

- Reconnect the fuel line to the new filter and close the access panel and start the engine.

- Allow it to run for a few minutes to ensure that the new filter is working properly. shut off the engine and check for any leaks.

3. Tracks That Won’t Stay On

If your excavator’s tracks keep coming off, it is likely due to a problem with the track tensioner. The track tensioner is responsible for keeping the tracks tight against the wheels.

If your mini excavator tracks are too loose, you can add more grease so the tension of the track could be solved. Here’s how:

- Park the mini excavator on a level surface and set the parking brake.

- Place a block under one of the tracks to keep the excavator from rolling.

- Locate the grease fittings for the track tension adjustment on the bottom of the machine. There should be two grease fittings, one on each side of the track.

- Remove the grease cap from one of the fittings and insert a grease gun into the fitting. Pump the handle of the gun until grease comes out of the other fitting. This will equalize the pressure on each side of the track, making it easier to adjust.

- Insert a screwdriver into the tension adjustment screw on one side of the track. Turn the screwdriver clockwise to tension the track. Continue turning the screwdriver until the track is tight, but not too tight.

- Repeat the same process on the other side of the track.

The same process goes for a mini excavator with steel tracks.

4. Broken Boom

If your excavator’s boom breaks, it is likely due to metal fatigue. Metal fatigue is caused by repeatedly bending and flexing the metal.

Replacing a boom is not difficult, but it does require some knowledge of the machine.

- The first step is to remove the broken boom from the mini excavator. This can be done by removing the bolts that hold the boom in place.

- Once the broken boom has been removed, the new boom can be installed. The process is the same as installing the old boom, except that the new boom will be in a different position. It is important to make sure that the new boom is properly aligned before bolting it in place.

- After the new boom has been installed, the mini excavator is ready to use. Be sure to follow the proper procedures for using and maintaining the machine to avoid future problems.

5. Broken Bucket

One of the most common problems that occur with mini excavators is a broken excavator bucket. The bucket is the part of the excavator that is used to scoop up dirt, sand, or other materials. If it breaks, it can be very difficult to continue using the excavator.

Fortunately, replacing a broken bucket on a mini excavator is not as difficult as it might seem.

With a few simple tools and a little bit of know-how, you can have your excavator up and running in no time.

Here’s what you’ll need to do to replace a broken bucket on a mini excavator:

- Park the excavator on level ground and set the parking brake and disconnect the battery.

- Raise the boom and bucket to their highest positions and remove the quick coupler pin (this is usually located on the side of the bucket).

- Remove the two bolts that secure the cutting edge to the bucket (these are usually located at the top of the bucket).

- Remove the four bolts that secure the bucket to the boom (these are usually located at the bottom of the bucket).

- Remove the old bucket from the excavator.

- Install the new bucket onto the excavator & secure the bucket to the boom with the four bolts.

- Attach the cutting edge to the bucket with the two bolts and raise the bucket and quickly coupler pin into place.

- Reconnect the battery and test the excavator to make sure everything is working properly.

If you follow these steps, you should have no problem replacing a broken bucket on your mini excavator. With a little bit of patience and some basic knowledge, you can get your excavator back up and running in no time.

6. Broken Swing Motor

If your excavator’s swing motor breaks, it is likely due to metal fatigue. Metal fatigue is caused by repeatedly bending and flexing the metal.

To fix this problem, you will need to replace the swing motor.

There are a few steps you’ll need to follow in order to replace the swing motor in your mini excavator.

- First, you’ll need to disconnect the hydraulic lines that are attached to the motor.

- Next, remove the bolts that are holding the motor in place.

- Once the motor is removed, you can install the new one and reattach the hydraulic lines.

- Finally, test the new motor to make sure it’s working properly.

7. Broken Hydraulic Pump

If your excavator’s hydraulic pump breaks, it is likely due to metal fatigue. Metal fatigue is caused by repeatedly bending and flexing the metal.

To fix this problem, you will need to replace the hydraulic pump.

This is a fairly simple process that can be done by most people with basic mechanical skills.

Here are the steps you need to follow to replace the excavator’s hydraulic pump.

- Begin by disconnecting the battery and all electrical power to the excavator. This will ensure that there is no chance of electrocution while working on the hydraulic pump.

- Next, remove the access panel to the hydraulic pump. This will give you access to the internal components of the pump.

- Once you have access to the pump, remove the old pump and replace it with a new one. Make sure that all of the connections are secure before turning on the power to the excavator.

- Finally, test the new hydraulic pump by operating the excavator. If everything is working properly, you should now have a fully functioning mini excavator.

8. Broken Hydraulic Cylinder

If your excavator’s hydraulic cylinder breaks, it is likely due to metal fatigue. Metal fatigue is caused by repeatedly bending and flexing the metal.

To fix this problem, you will need to replace the mini excavator hydraulic cylinder.

This is a fairly simple process that can be done by most people with basic mechanical skills.

9. Electrical Problems

If your excavator is having electrical problems, it is likely due to a problem with the wiring.

The wiring on excavators is often very complicated, so don’t try to solve this problem by yourself, and it is best to leave this repair to a professional.

Why do These Problems Occur With Mini Excavators?

An excavator is an expensive piece of construction equipment. Because of this, it’s important that they are well-maintained and operated correctly.

Unfortunately, this doesn’t always happen and due to lack of knowledge, many problems may arise even if you purchase this tool to ease your chores:

#1. Non-Maintenance

One of the most common problems with excavators is that they are not properly maintained.

This can lead to a number of issues, such as breakdowns, malfunctions, and accidents.

#2. Operated Incorrectly

Another common problem with excavators is that they are operated incorrectly.

This can also lead to a number of issues, such as breakdowns, malfunctions, and accidents.

#3. Lack of Knowledge

A final problem that can occur with excavators is that the operator may not be properly trained.

This can lead to a number of issues, such as incorrect operation, mishaps, and accidents.

Final Verdict

Mini excavators are not perfect and neither are we, humans. In fact, there are quite a few problems that can occur when using this machine whether you purchase a used mini excavator or a brand new one. However, these problems can be easily avoided if you know what is their root cause and how to fix them.

These are just some of the most common problems that people have with their smallest mini excavator.

If you have any major problems with your excavator that you just can’t fix, it is best to consult a professional or take equipment repair service. You can also contact us for more information.