Introduction

Micro excavators are quite popular these days on construction sites. These little machines are extremely efficient at carrying out multiple tasks at your sites. The tasks can vary, such as lifting, digging, trenching, landscaping, loading, unloading, and much more. These tasks can also be done using manly power, especially when it comes to lifting some easy stuff, people tend to use micro excavators. Do you know why?

Micro excavators can save energy, costs, and time and perform tasks more efficiently. For example, you don’t need to hire expensive operators to perform the tasks. The saved cost can be used to invest in excavators and earn a huge profit. Moreover, it may take too much time and energy to perform the tasks through manly power.

However, you must know how to carry out the tasks safely. Because if you don’t take safety measures, the excavator can also become a dangerous machine for you. For example, it can cause fatal injuries and even death of your workers if not handled properly.

There comes with a user manual from the manufacturer or supplier when purchasing your excavators. The best thing you can do is to read the user manual completely to know about instructions and warnings. In case you don’t have a user manual, don’t worry.

This article has everything that you should know. So, you will learn about the safe lifting of materials using an excavator on your construction site. Continue reading!

You Should Learn The Fundamentals First For Lifting Through A Micro Excavator

Hydraulic Lifting Capacity & Tipping Load Of Compact Excavator

When determining the rated lifting capacity of an excavator, you need to consider two factors. These factors are tipping load and hydraulic lifting capacity.

In hydraulic lifting capacity, the hydraulic power of your micro excavators will limit the lifting capacity. On the other hand, the tipping load determines the point at which your excavator starts tipping.

Perform lifting tasks based on hydraulic limitations since your excavators have limited hydraulic standards.

Tests Are Conducted To Develop Lifting Charts For Lifting Through A Micro Excavator

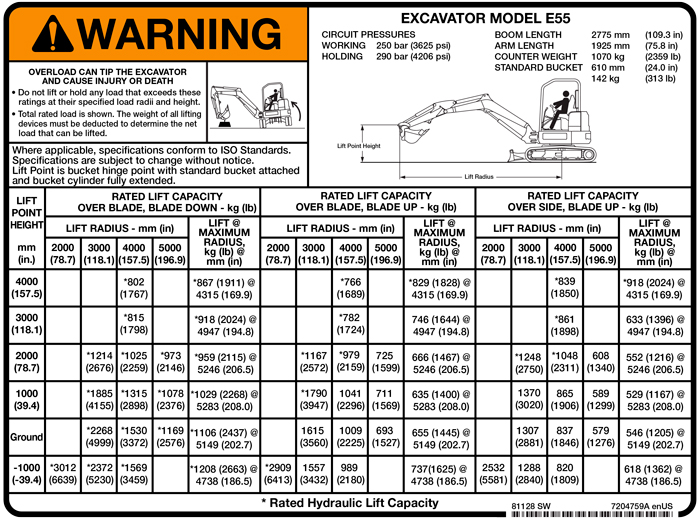

Your manufacturers conduct various tests to determine the maximum lifting weight, height, and distance for excavators. These tests are conducted according to ISO 10567. According to the measurements taken by these tests, manufacturers develop lifting charts that you should follow. These charts are given in the user manual of your micro excavator chart.

Understanding The Lift Chart Of Your Micro Excavator

It is important to know the basics of the lifting chart given in the user manual of the lifting devices. According to some high-quality brands, such as Bobcat, the machine’s standard configuration is given in the lifting charts of excavators.

It has been recommended to avoid any attachments or objects that increase the weight of excavators while operating. It reduces the lifting capacity when lifting heavy loads.

You can find several lifting charts for your small, medium, or large-sized dozer blade or excavators. These charts are based on bucket size, arm length, and boom length. According to the excavators specialist at Doosan excavators, you should pay attention to whether the bucket weight is given in the chart.

The bucket weight varies among different manufacturers. Moreover, it helps to determine the lifting capacity of your excavators. It is also possible that the bucket you are using might not match the standard weight requirements given in the chart.

In the chart below, the machine’s hydraulic capacity limits the rated loads marked with an asterisk. According to tests, these loads are not exceeding 87 percent of hydraulic lift capacity. On the other hand, the machine’s stability and/or tipping capacity limits the rated loads without an asterisk. These are not exceeding 75 percent of the tipping load.

Determination Of Life Point Height

This is something that you have to do next in understanding the lift ratings. In the lift chart given above, you can see the far-left designated lift point. Note that this reading doesn’t denote the distance from the ground to the object you need to lift.

When determining the lift point height, you must consider how high you will lift the object. It also includes the height of the load, the lifting device’s length, and the targeted height. You must figure out the lifting radius from the swing point’s centerline. You can see this distance measurement in the lift chart’s top row.

Moreover, if you use outriggers or dozer blades with your excavator, you must consider the portion reflecting position during excavation.

The next step is to figure out the point at which the lifting radius and lift point height intersect. The number present at that point is the rated lifting capacity of your excavator. If that place is blank, your micro excavator doesn’t have lifting capacity for that point. Therefore, you should not attempt lifting.

Lifting capacity will decline while moving to the right of the chart.

You Should Also Consider Jobsite Before Attempting To Lift Anything

No matter what task you perform using your micro excavator, it is always important to consider your job site. Some important considerations for your job site are listed below:

-

Strength of supporting surfaces beneath your micro excavator

-

Operating condition of your micro excavators

-

Weather conditions

-

Obstructions that are available at the job site.

-

Proper movement of excavator with suspended load, etc.

Lifting Checklist Of Micro Excavators At Your Jobsite

- When attempting to make lifting services at your job site, make sure you do it on a flat surface. It is because when you do it on uneven surfaces, there are more chances of tipping your micro excavator. Hence, it can cause injuries as well as accidents. You can also use lifting points designated by your manufacturer.

- You should not attempt to alter your micro excavator. But, you should maintain the excavator regularly.

- You should lift squarely over the front or side of the machine. Some excavators also come with lifting mode control. If you also got this feature, you should turn it on.

- You should try your best to keep the load low since it can help you to balance your micro excavators.

- You should not attempt to swing the load quickly since it can cause damage to the excavator as well as the Jobsite. Make sure you are moving it here and there slowly.

- You should not perform lifting jobs near the public or where people are standing. It may cause injuries. Moreover, you should not load over the equipment or personnel. It can also be very harmful.

- Excessive side load conditions can be created through unexpected wind gusts if the load’s surface area is too large. You should take the lines workers must hold on opposite the load. It can help to prevent side loading caused by wind gusts.

- You should keep the designated lift point over the load directly. If the line is twisted, the load can become unbalanced. It will start to rotate suddenly. However, you can use short slings to prevent excessive swayings and load swings.

- The lifting eye should be kept straight below the bucket pin and centerline of the arm. It will help you primarily support the load’s weight through the pin.

- While performing the lifting jobs on-site, you should always monitor overhead restrictions. These restrictions can be either structures or simply power lines.

- Before lifting anything, you must consult the manufacturer or supplier regarding safety measures.

Important Key Points To Know Before Performing The Lifting Operations

- You should ensure that your micro excavator is rated to lift the targeted load from one place to another.

- Ensure your operators are trained enough to carry out the lifting tasks properly. Moreover, they should understand all the standards and instructions on the lifting chart.

- It is always recommended to inspect your micro excavators before performing any heavy tasks such as lifting.

- As mentioned earlier, keeping your machine on a stable surface is also important.

- Once stabilizing the machine, it is important to keep it in the right position to carry out the lifting tasks.

- You should clear the area and move workers and related obstructions from the targeted area.

- Slower movements of the excavator will ensure stabilized movements. Moreover, you can easily control the whole process without causing accidents or injuries.

- Make sure that there is no damage to the load when lifting it. You need to ensure the secure lifting of loads.

- If you want to minimize the risks of damage to the micro excavator, you should always follow the manufacturer’s instructions.

Conclusion

Lifting through your micro excavator may seem very complex after reading this article. However, if you have practiced the whole process once, there is no need to worry about anything.

If you don’t know how to perform all these tasks by yourself, you should try to hire an expert operator. It is better to spend some money on operations than damaging the machine.

Besides these factors, choosing the right attachment for lifting is important, such as a standard or short arm. It depends on the type of load that you need to lift from one place to another. You can also ask your manufacturer to guide you about choosing the right attachment for lifting your materials.

Contact Us now if you are looking for a reliable and experienced excavator manufacturer.